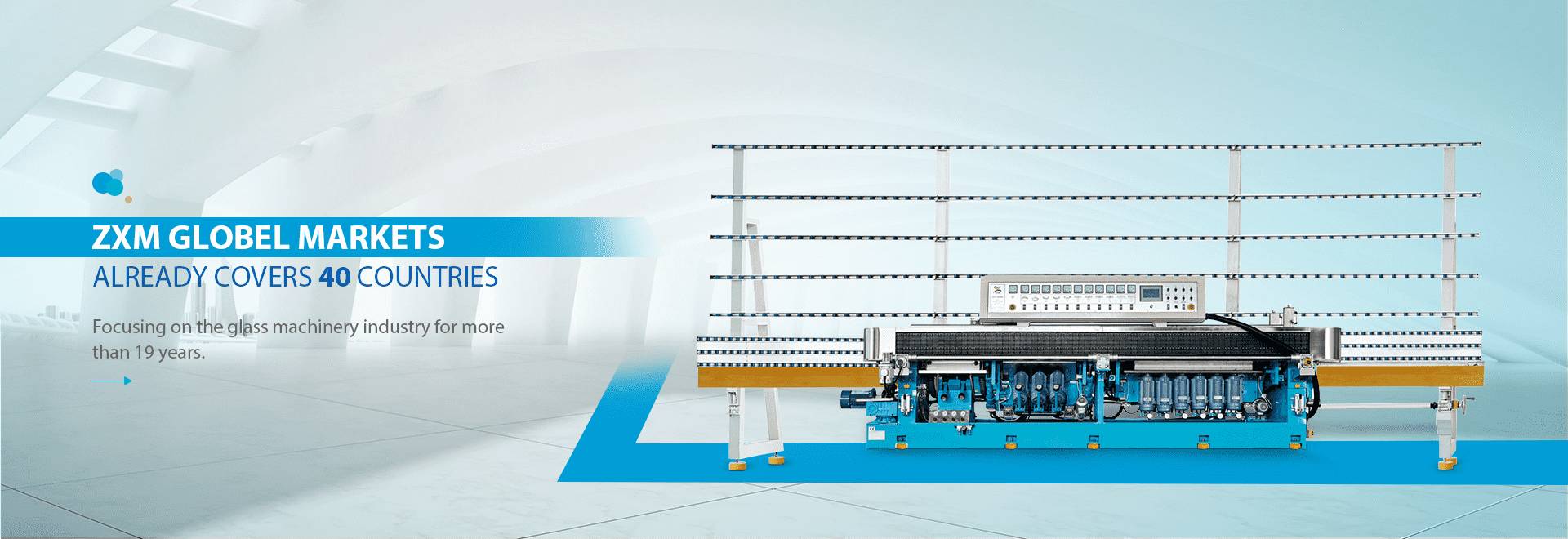

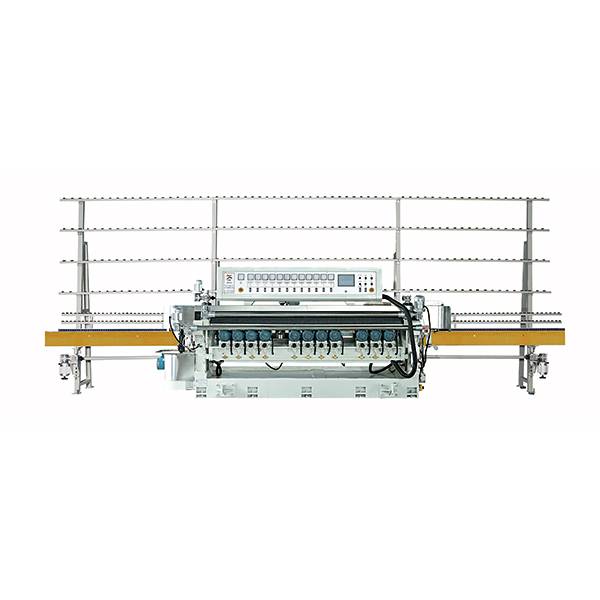

Renewable Design for Glass Corner Polishing Machine - 12 motors Italian ball bearing beveling machine PLC computer – Zhengxing

Renewable Design for Glass Corner Polishing Machine - 12 motors Italian ball bearing beveling machine PLC computer – Zhengxing Detail:

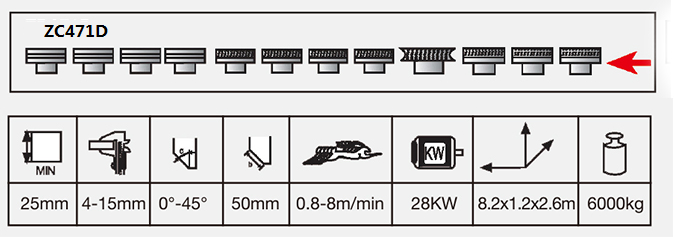

ZC471D

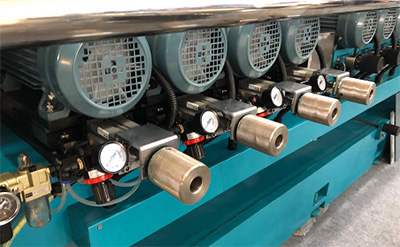

Pneumatic polishing motor

Back conveyor height adjustment system

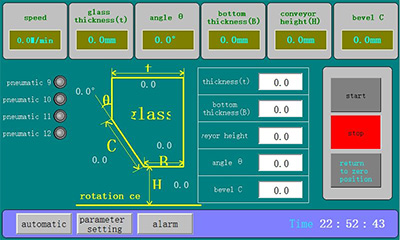

Easy operation interface

Ball bearing conveyor, Cast steel base, NSK bearing

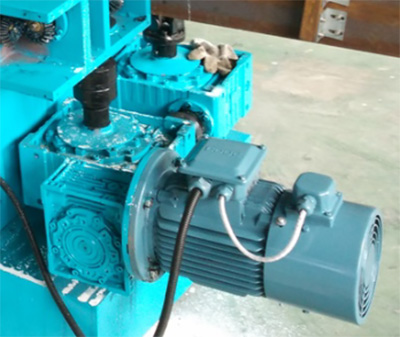

frequency inverter motor

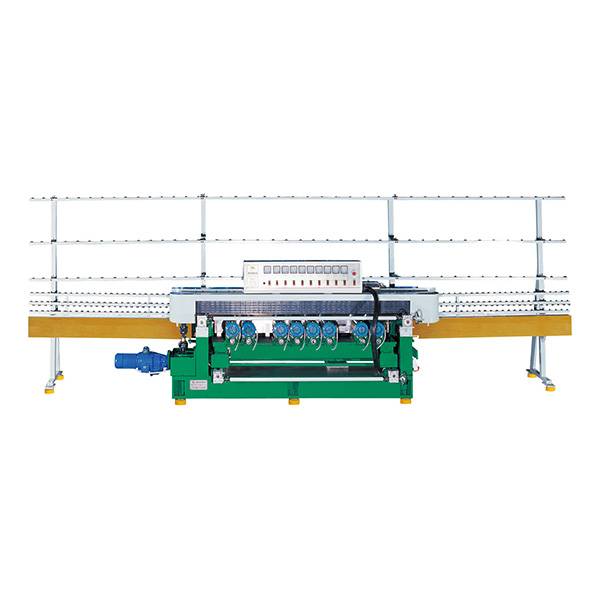

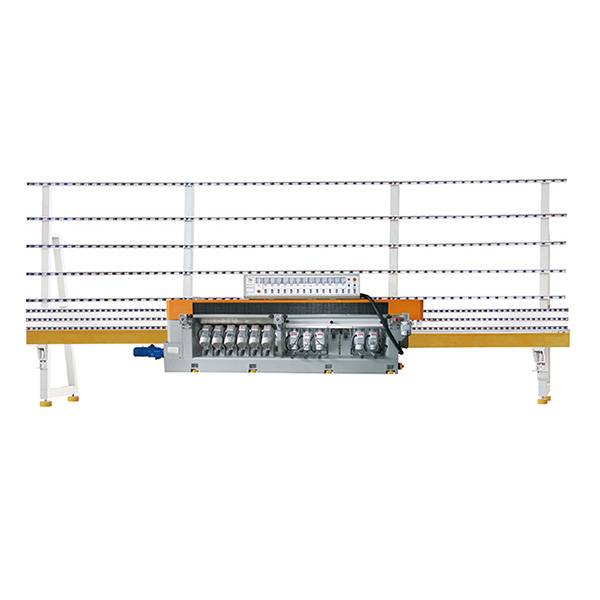

Machine Introduction

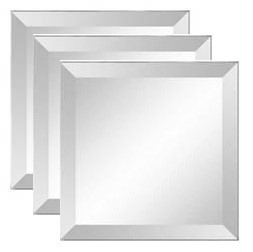

This machine is designed to make bevel on small glass and big glass. The back conveyor track can be moved up and down according to glass size. For small glass size, the back conveyor track can be moved upward. For big glass size, the back conveyor track can be moved downward.

This glass beveling machine use ball bearing conveyor system. The drive gear directly drive the roller of each pad. This system is very strong and suitable for small glass (30mmx30mm) and heavy glass(4mx4m) processing. It is the very precise and move very stable and steady. All the bearing use NSK produced in Japan.

Back conveyor has cleaning brush, which ,maintain a clean surface and guarantee working result.

It is PLC controlled, with touch panel working system. screen show angle, bevel Width, bottom thickness, it is easy to operate. The machine use ABB spindle, speed inverter system. It has high working efficiency and precision.

Basement and frame are made of cast iron to ensure stability and solidity.This machine use high precision low vibration ABB motor, specially for beveling machine.

Loading/offloading conveyor adopt timing belt.

Front rail movement is motorized, it can move in parallel to adapt to different glass thickness. There is a mechanical thickness readout to show conveyor opening.

Glass support frame Use aluminum bar with blue plastic roller.

Lubrication: the machine equipped a automatic lubrication pump, which lubricate the front and back conveyor.

All the sliding surfaces (including front conveyor movement, grinding beam moving section, motor plates) are lubricated by oil system. The well designed oil lubrication system make sure machine’s life time and long-time smooth running.

Working speed adjustment through frequency inverter system. The inverter use Mitsubishi.

Ampermeter meter check the wheel absorption.

Water is circulated in the machine and stainless water tank. Wheel tank outlets connect with one stainless drain pipe which is very easy for installation. The square water tube for water inlet is connected with each wheel nozzle.

Felt wheel use pneumatic system.

Technical parameters

|

Item |

Parameter | Range |

|

1 |

working speed: |

0.8-8m/min |

|

2 |

Minglass size: |

30mmx30mm |

|

3 |

Glass thickness: |

4mm-15mm |

|

4 |

Max. bevel width: |

50mm |

|

5 |

Bevel angle: |

0°~45° |

|

6 |

Total power: |

30kw |

|

7 |

Base Dimension: |

8.2×1.22.6m |

Product detail pictures:

Related Product Guide:

No matter new customer or old customer, We believe in long term and trusted relationship for Renewable Design for Glass Corner Polishing Machine - 12 motors Italian ball bearing beveling machine PLC computer – Zhengxing , The product will supply to all over the world, such as: Afghanistan, Seattle, Tunisia, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.