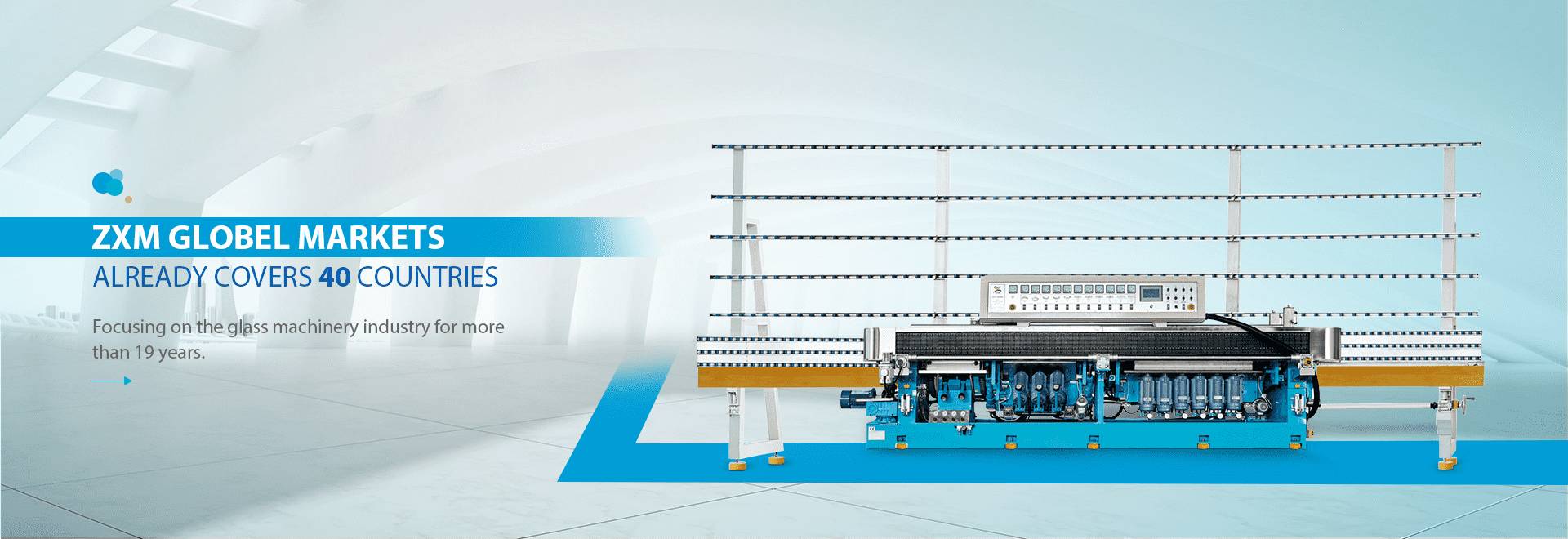

Welcome to our websites!

-

10 motors automatical ball bearing heavy duty glass edging mitering machine

This machine has 6 motors which can process glass bottom edge and front arris(0-45 degree), with 2 motors for front seaming and 2 motor for rear seaming. This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx400mm) and heavy glass (4mx4m) processing. The machine has a glass thickness protection mechanism. When wrong thickness glass is put in the machine, the machine will stop automatically. This protects the bearings from crushing. The machine adopt PLC control and operator interface. The working speed can be adjusted via the stepless regulator. The processed glass surface is very bright and smooth, approaching to the original glass surface. This machine is also featured by wide processing range and easy operation. -

11 motors automatical ball bearing variable angle glass edging mitering machine

This machine has 6 motors(No.1-No.6) which can process glass bottom edge and front arris(0-60 degree), 3 motors (No.7-No.9) which can process glass miter edge and also bottom edge, with 2 motors for rear seaming. All process is finished at one travel. To make flat edging/polishing, No.1-No.6 motors need to stay at ZERO degree and No.7-9 motor can be changed to 45 degree for front arris. To make miter and bottom edge, No.1-No.6 motors can be adjusted to the requested degree and turn No.7-No.9 motors to ZERO degree for bottom edge processing. This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx40mm) and heavy glass (4mx4m) processing. -

15 motors automatical ball bearing variable angle glass edging mitering machine

The first section 6 motors(No.1-No.6) process glass bottom edge and front miter edge (0-60 degree), 2 motors (No.7-No.8) for back arris seaming and 2 motors (No.9-No.10) for front arris seaming. No.11.No.12 and No.13 motors are for bottom edge grinding and final polishing when No.1-No.6 motors for front miter processing. The last two wheels are for front and back arris polishing. All process is finished at one travel.

This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx40mm) and heavy glass(4mx4m) processing. The top brackets structure can make conveyors running stably to work very small glass 40mm size. -

automatical chain system variable angle glass edging mitering machine

This machine can do normal flat edge polishing, it can also make miter edge of 0-45 degree. This machine use PLC control and touch panel operating system. The machine can run in automatic mode and manual mode. The front 4-6 motors can adjust angle from 0 degree to 45 degree for polishing bottom edge and miter edge.