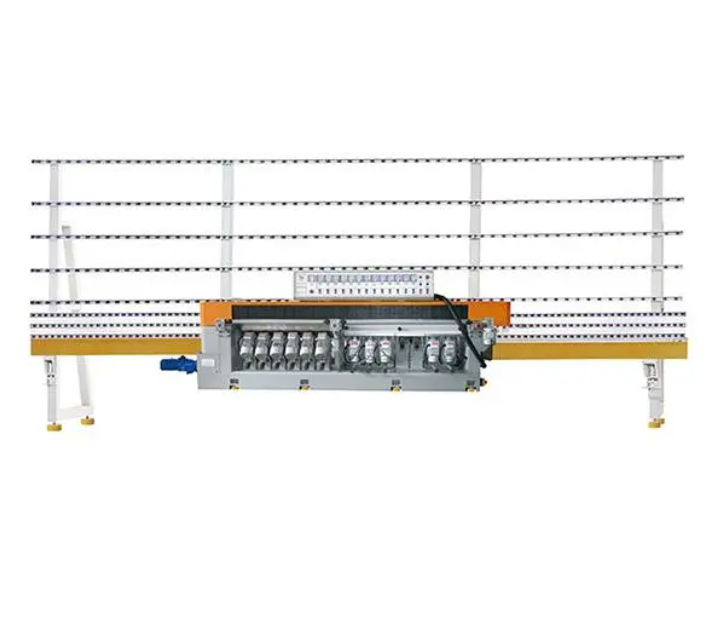

Glass edge grinding machine is a machine and equipment used to process and polish the edges of glass. Its development has gone through the following stages:

1. Manual edging stage: The earliest glass edging was done by hand. Workers needed to use hand tools to polish the edges of the glass. This method was inefficient and the quality was difficult to guarantee.

2. Traditional mechanical edging stage: With the advancement of mechanical technology, glass edging machines began to appear. These machines usually use turntable or pulley abrasives, which can automatically perform edge grinding operations, improving efficiency and processing quality.

3. CNC glass edge grinding machine stage: With the development of CNC technology, CNC (Computer Numerical Control) glass edge grinding machine came into being. Through computer control, the machine can be accurately controlled to perform various edge grinding operations, improving processing accuracy and stability.

4. Automation and intelligence stage: In recent years, with the rapid development of industrial automation and artificial intelligence technology, glass edge grinding machines have become more and more intelligent. Some advanced edge grinding machines have automated workflows, intelligent operating interfaces, and can even automatically detect and repair glass defects.

Generally speaking, glass edging machines continue to pursue higher processing accuracy and efficiency from manual edging to traditional mechanical edging to the application of CNC technology. In the future, with the further development of technology, we can foresee that glass edge grinding machines will be more intelligent, automated, and able to cope with more complex processing needs.

Post time: Apr-23-2024