Massive Selection for Cnc Glass Edge Polishing Machine - 9 motor small glass beveling machine PLC control ZX261D 361D 371D – Zhengxing

Massive Selection for Cnc Glass Edge Polishing Machine - 9 motor small glass beveling machine PLC control ZX261D 361D 371D – Zhengxing Detail:

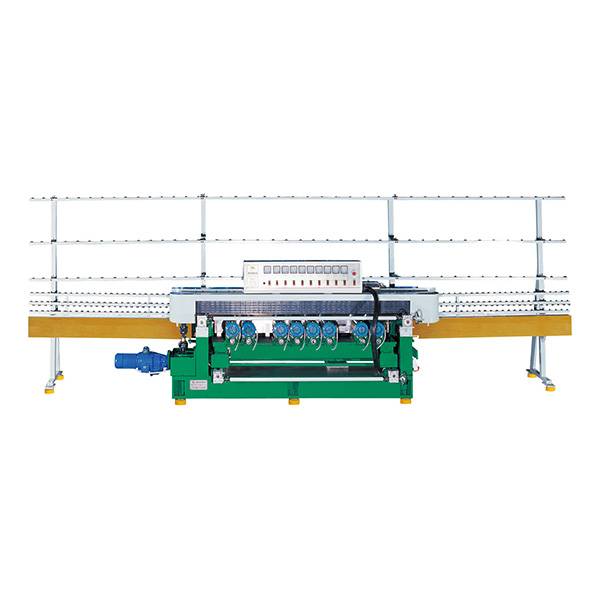

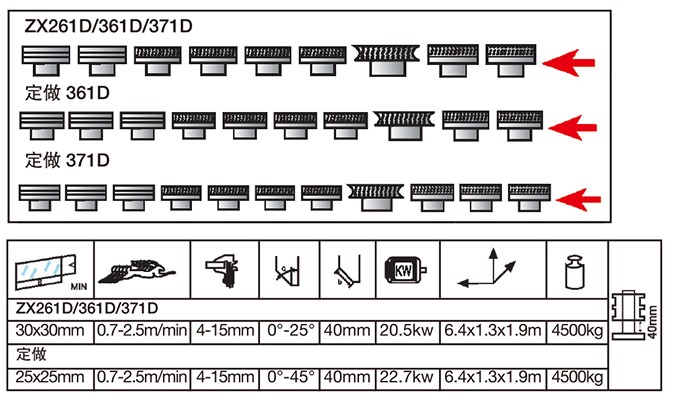

ZX261D/361D/371D

Back conveyor height adjustment system

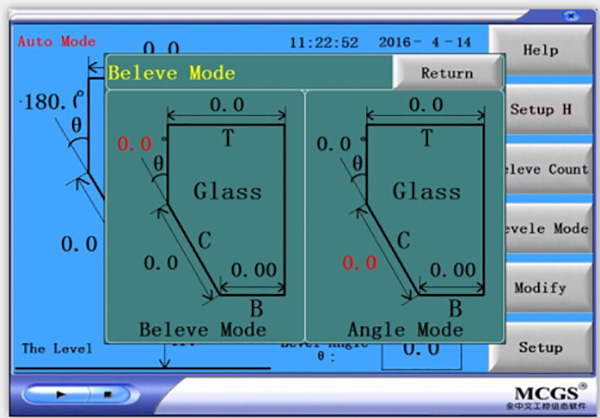

Automatic operation interface

Chain & bearing combined conveyor

Machine Introduction

This machine is designed to make bevel on small glass and big glass. The back conveyor track can be moved up and down according to glass size. For small glass size, the back conveyor track can be moved upward. For big glass size, the back conveyor track can be moved downward.

This machine adopt PLC control and operator interface. The Screen can show glass thickness, bevel angle, bevel width and back track height.

Basement and frame are made of cast iron to ensure stability and solidity.

Back Conveyors use chains transmitting system. The pads are connected by single big roller chain. Each pad has a guide bearing, which guarantee high precision when conveyor is running on the tracks.

The pads of front conveyor have changeable rubber pads which are specially designed to grip small glass 30mm, which can be replaced independently after wear-off. This structure guarantee glass is stably moved. The working precision is high.

Back conveyor has cleaning brush, which ,maintain a clean surface and guarantee working result.

Motor use high precision low vibration ABB motor, specially for beveling machine.

Loading/offloading conveyor adopt timing belt.

Front rail movement is motorized, it can move in parallel to adapt to different glass thickness. There is a mechanical thickness readout to show conveyor opening.

Glass support frame use aluminum bar with blue plastic roller.

The machine is equipped a manual lubrication pump, which lubricate the sliding part of motor plate and front conveyor moving system. Front and back conveyor should be greased by solid grease.

Working speed adjustment is through speed regulator, manually.

Amperometer meter check the wheel absorption.

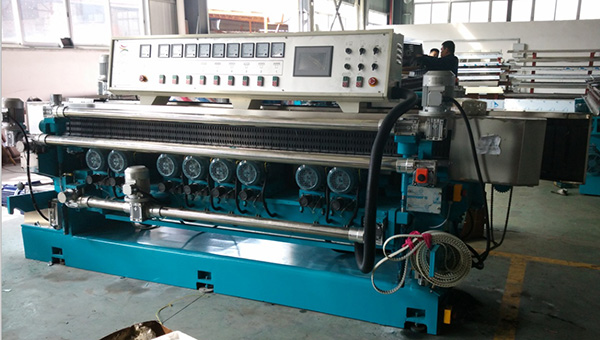

Water system

Water is circulated in the machine and stainless water tank. Wheel tank outlets connect with one stainless drain pipe which is very easy for installation. The square water tube for water inlet is connected with each wheel nozzle.

Back pads washing unit

Technical parameters

|

Item |

Parameter | Range |

|

1 |

Spindles: |

9 heads.10 heads, 11 spindle |

|

2 |

Speed: |

0.8m-4m/min |

|

3 |

Max. bevel width: |

40mm or 50mm |

|

4 |

Min. glass size: |

30mmX30mm |

|

5 |

Glass thickness: |

4mm-15mm |

|

6 |

Bevel angle: |

0°-25°/ 0°-45° |

|

7 |

Total power: |

21 KW 23KW 25KW (380V 50Hz) |

|

8 |

Total dimension: |

6.7mX1.1mX2.2m |

|

9 |

Weight: |

5000Kg |

Product detail pictures:

Related Product Guide:

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for Massive Selection for Cnc Glass Edge Polishing Machine - 9 motor small glass beveling machine PLC control ZX261D 361D 371D – Zhengxing , The product will supply to all over the world, such as: Honduras, Pretoria, Durban, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.