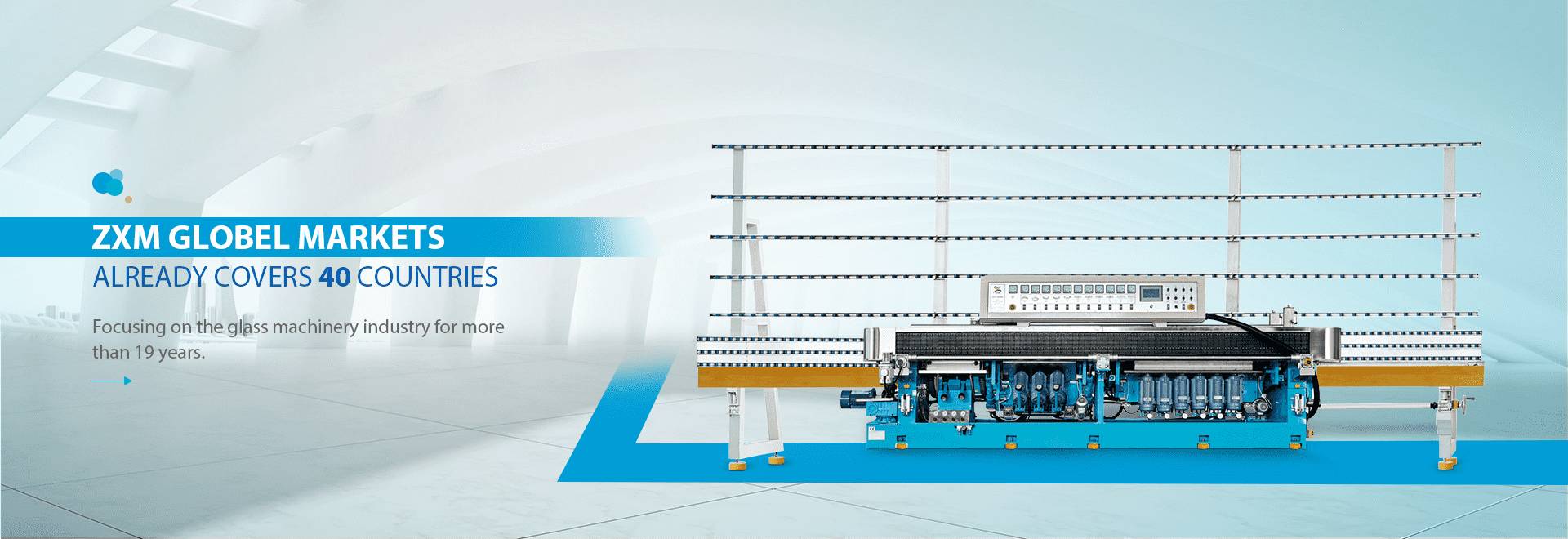

Hot Sale for Glass Edge Grinding Machine - chain system automatic glass flat edge polishing machine puenmatic – Zhengxing

Hot Sale for Glass Edge Grinding Machine - chain system automatic glass flat edge polishing machine puenmatic – Zhengxing Detail:

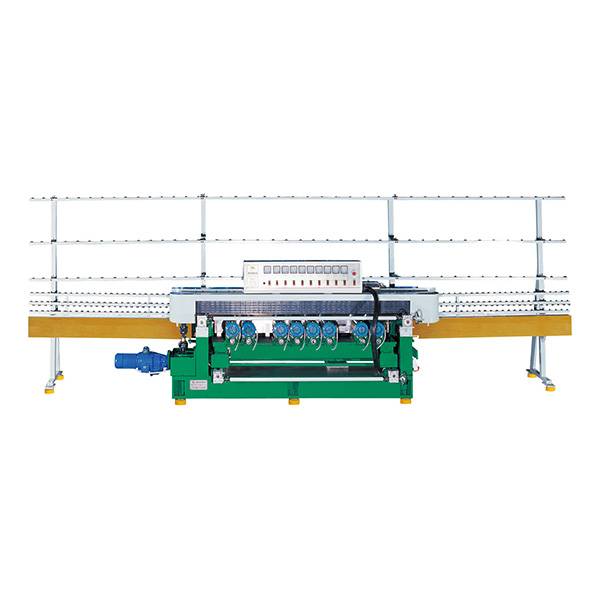

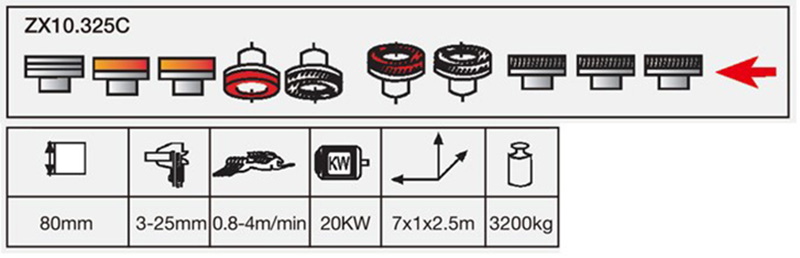

ZX10.325C

Mitsubishi PLC control and touch panel operating system

reinforced middle support

Motorized to adjust different glass thickness

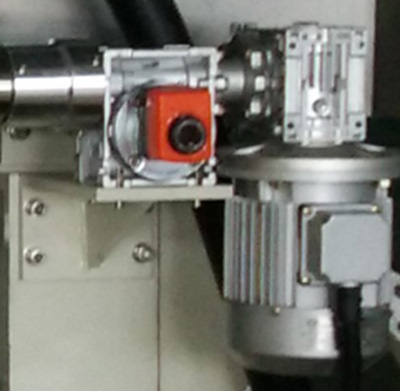

high quality drive motor- Starlight brand

high quality motor- CDQC brand

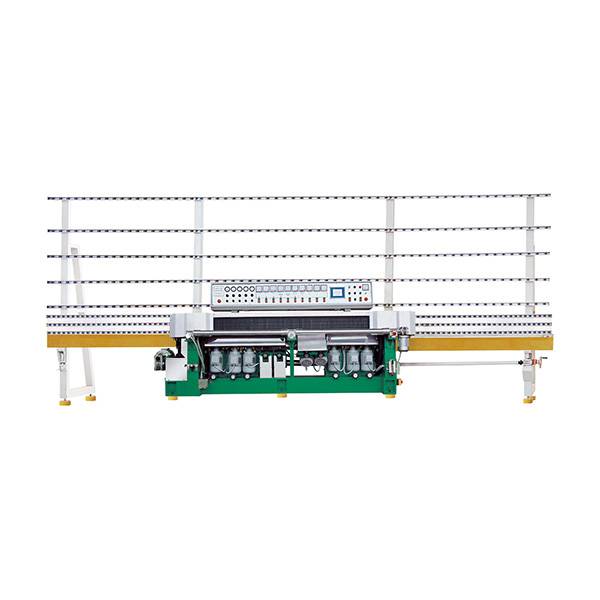

Machine Introduction

a) Control system:

This machine use PLC control and touch panel operating system. The machine can run in automatic mode and manual mode In manual mode, the polishing wheel can still work in air system. The big advantage is this machine separate the control system with electrical system, so the machine can work even the automatic system has fault.

b) Basement and frame:

Are made of thick iron to ensure stability and solidity

c) Conveyor:

chain transmitting system,pads are connected by the two chains. Pads are made of nylon, stretchy rubber pad is attached on the nylon base. Rubber pads can be replaced after it wear off.

The machine has a reinforced middle support. This has a important role to rectify the conveyor straightness in case it get some deformation in a long run. (Pic. II)

d). Loading/offloading conveyor:

Timing belt. It can adjust height to set different glass removal. The height is shown on disk readout.

d) A manual lubrication oil pump can pump the lubrication oil to the sliding plates for motor movement and front conveyor movement. The front and back conveyor need to be lubricated by grease manually smeard.

e) Front rail movement:

Motorized, it can move in parallel to adapt to different glass thickness. (Pic. II)

f) Working speed adjustment:

through speed regulator (drive motor), manually, the speed is shown on digital meter. The drive motor made by Starlight company, which is a high quality factory in China.

g) Working motor is made by CDQC.

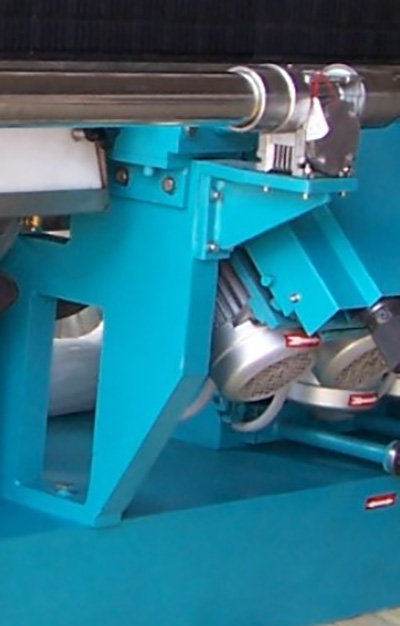

h) Water system

Water is circulated in the machine and stainless water tank. Wheel tank outlets connect with one stainless drain pipe which is very easy for installation. (pic.IV). The square water tube for water inlet is connected with each wheel nozzle.

i) Glass support frame

Use aluminum bar with blue plastic roller.

j) Amperometer meter:

check the wheel pressure.

k) Spindles for arris adopt drag plates structure, which is no vibration in working.

Technical parameters

| Item | Parameter | Range |

| 1 | Working Speed: | 0.8-4m/min |

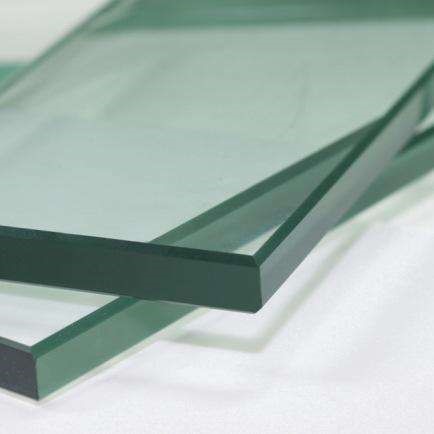

| 2 | Glass thickness: | 3mm-25mm |

| 3 | Total Weight: | 3200kg |

| 4 | Min. glass Size: | 80mmx80mm |

| 5 | Base Dimension: | 7×1×2.5m |

| 6 | Total power: | 20kw |

Product detail pictures:

Related Product Guide:

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for Hot Sale for Glass Edge Grinding Machine - chain system automatic glass flat edge polishing machine puenmatic – Zhengxing , The product will supply to all over the world, such as: Lebanon, Angola, Milan, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.