Good Quality Glass Wave Beveling Machine – automatical chain system variable angle glass edging mitering machine – Zhengxing

Good Quality Glass Wave Beveling Machine – automatical chain system variable angle glass edging mitering machine – Zhengxing Detail:

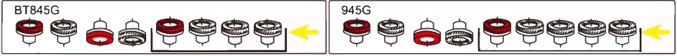

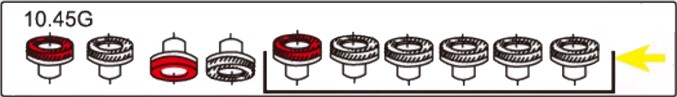

ZX845G/ ZX945G/ZX10.4G

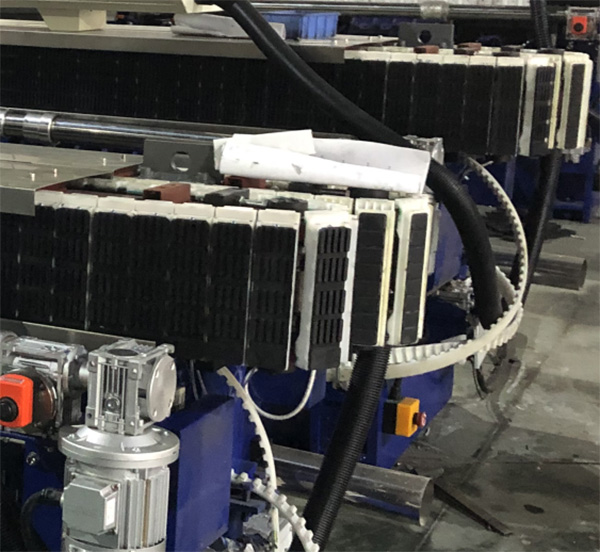

Chain conveyor

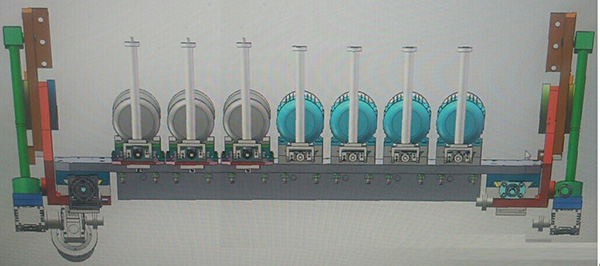

Variable angle rotation system

Machine Introduction

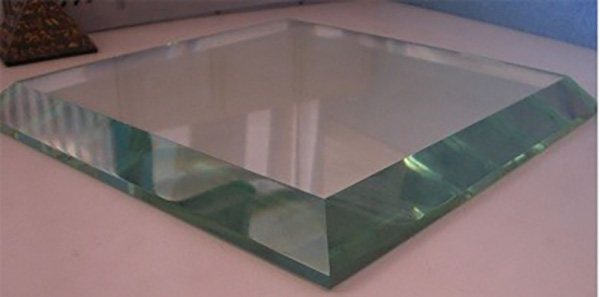

This machine perform normal edge polishing and miter edge polishing

a) Control system:

This machine use PLC control and touch panel operating system. The machine can run in automatic mode and manual mode.

b) Variable angle change range

The five bottom wheel can adjust angle from 0 degree to 45 degree. The rotation system use twin shafts supporting structure, the motor beam is supported from two ends which give a very good balance and keep same precision during rotation.

c) Cooling water system.

The wheel tank of frontal 5 wheels adopts rotation system, which can adapt to the wheel according to the angle.

d) Basement and frame:

Are made of fabricated iron after heat treatment to ensure stability and solidity.

e) Conveyor:

chain transmitting system, pads move along the beam, rubber is fixed on the nylon pads.

The machine has a reinforced middle support. This has a important role to rectify the conveyor straightness in case it get some deformation in a long run.

f) Basement, support, conveyor

Are made of cast iron to ensure stability and solidity

g) This machine use high quality CDQC motor

h) Front rail movement:

Motorized, it can move in parallel to adapt to different glass thickness.

i) Loading/off loading conveyor

Time belts, the loading belts can adjust height to get different glass removal.

j) Glass support frame use Aluminum extrusion bar, with plastic rollers.

k) Working speed adjustment:

through speed regulator, manually.

l) Amperometer meter:

check the wheel pressure.

m) Spindles for arris adopt drag plates structure, which is no vibration in working.

n) Water system

Water is circulated in the machine and stainless water tank. Wheel tank outlets connect with one stainless drain pipe which is very easy for installation. (pic.IV). The square water tube for water inlet is connected with each wheel nozzle.

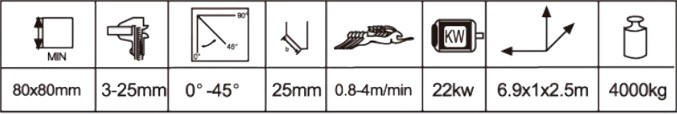

Technical parameters

|

Item |

Parameter | Range |

|

1 |

working speed: |

0.8-3.8m/min |

|

2 |

Glass thickness: |

3-25mm |

|

3 |

Miter angle: |

0- 45° |

|

4 |

Front miter removal : |

15 mm |

|

5 |

Min. glass size: |

100×100 |

|

6 |

Overall dimension(L.W.H): |

6900x1000x2500mm |

|

7 |

Weight: |

3000kg |

|

8 |

Installed power: |

18kw |

Product detail pictures:

Related Product Guide:

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for Good Quality Glass Wave Beveling Machine – automatical chain system variable angle glass edging mitering machine – Zhengxing , The product will supply to all over the world, such as: Austria, Chile, Saudi Arabia, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.