Chinese wholesale Glass Edger - automatic ball bearing ABB motor glass edging polishing machine – Zhengxing

Chinese wholesale Glass Edger - automatic ball bearing ABB motor glass edging polishing machine – Zhengxing Detail:

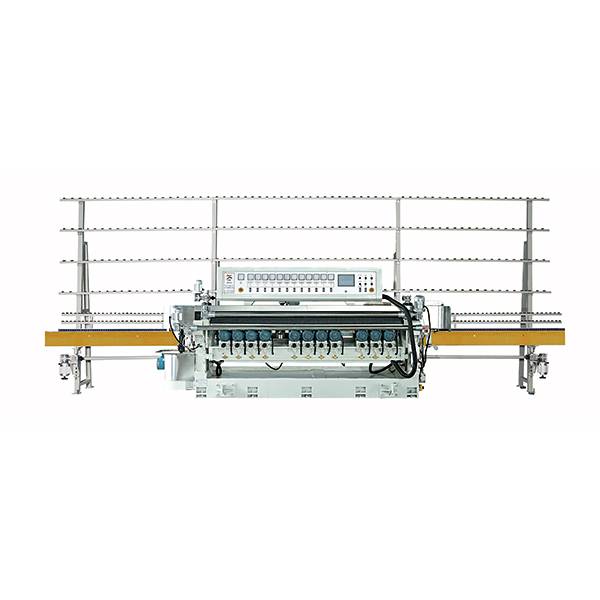

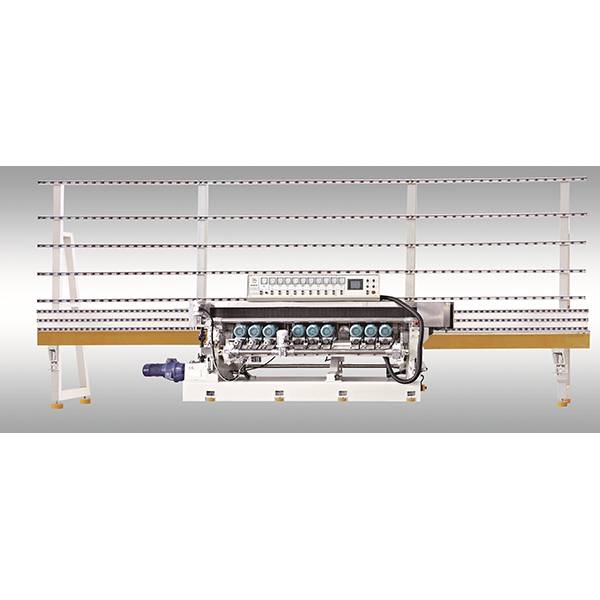

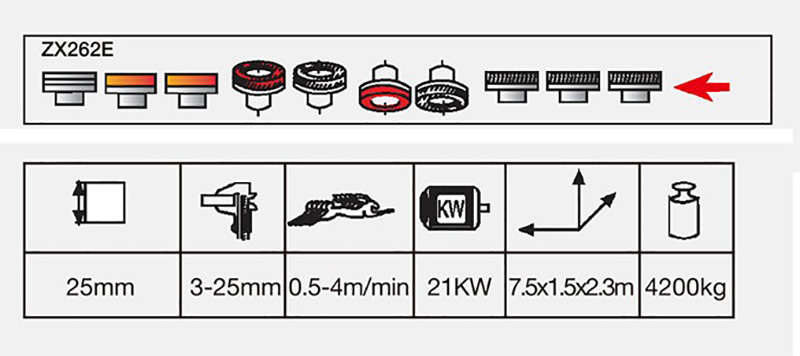

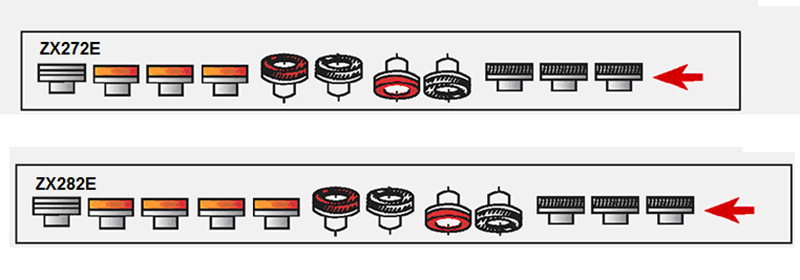

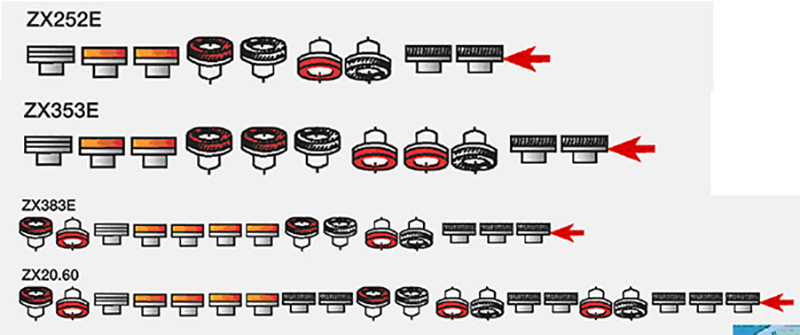

ZX262E/ZX272E/ZX282E

Mitsubishi PLC control and touch panel operating system

high precision ball bearing structure,stable movement & good waterproof performance

Back conveyor has cleaning brush, which ,maintain a clean surface and guarantee working result

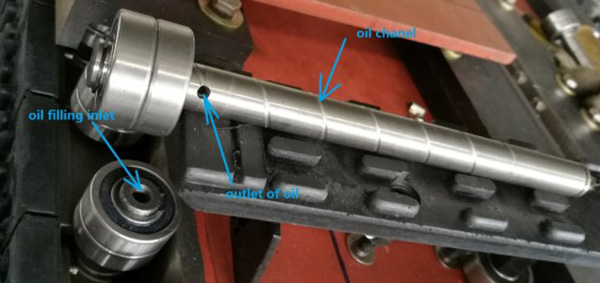

lubrication system

Stainless steel water circulating system

Machine Introduction

a) Control system:

This machine use PLC control and touch panel operating system. The machine can run in automatic mode and manual mode.

b) Conveyor:

Conveyor adopt chainless rolling transmitting system, which consists of three bearings rolling along high precision tempered steel guides, the movement of glass is very stable.

The bearings for front and back conveyor is lubricated automatically by the oil pump, the well designed oil route enable top and bottom bearings to get oil evenly.

Back conveyor has cleaning brush, which ,maintain a clean surface and guarantee working result.

c) The machine has a glass thickness protection mechanism. When wrong thickness glass is put in the machine. The machine will stop automatically. This protects the bearings from crushing.

d) Loading/off loading conveyor use timing belt. It can adjust height to set different glass removal.

e) Glass support frame use Aluminum extrusion bar, with support roller.

f) The conveyor cover is made in stainless steel.

g) The front conveyor movement is motorized. It can be adjusted through electrical button on working panel or adjustable automatically. The thickness is displayed on screen. There is also a mechanical readout to show glass thickness.

h) Working speed adjustment:

Working speed is adjustable through frequency inverter.

i) Spindles are driven by high quality ABB motors.

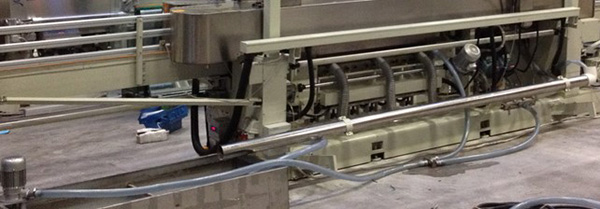

j) Water system

Water is circulated in the machine and stainless steel water tank. A stainless steel drainage pipe is installed on back of machine to drain water from wheels tank. Clean water is pumped to machine through a square water tube. Installation of water circulation system is very easy.

Technical parameters

| Item | Parameter | Range |

| 1 | Spindles: | 9 heads. |

| 2 | working Speed: | 0.1m-3.8m/min |

| 3 | Grinding depth: | 3mm |

| 4 | Max. arris width: | 2.5mm |

| 5 | Glass thickness: | 3mm-30mm |

| 6 | Min. glass Size: | 25mmX25mmX8mm |

| 7 | Total Power: | 19.85kw |

| 8 | Overall Dimension: | 8.0mx1.2mx2.0m |

| 9 | Total Weight: | 5700kg |

Product detail pictures:

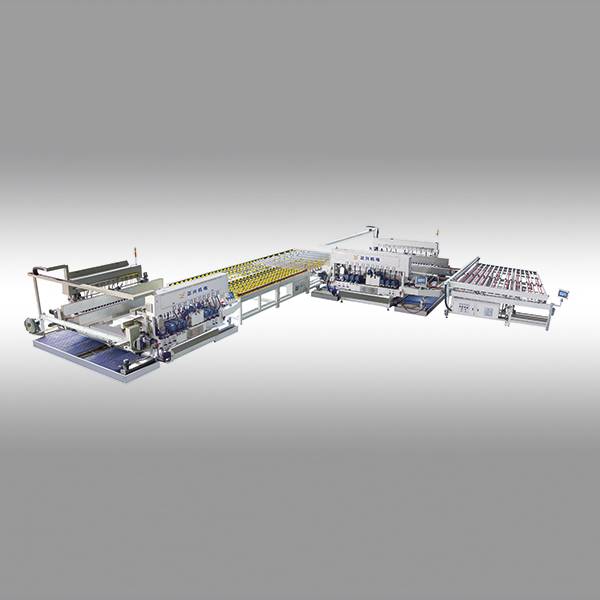

Related Product Guide:

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of Chinese wholesale Glass Edger - automatic ball bearing ABB motor glass edging polishing machine – Zhengxing , The product will supply to all over the world, such as: Montpellier, Rio de Janeiro, Armenia, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.