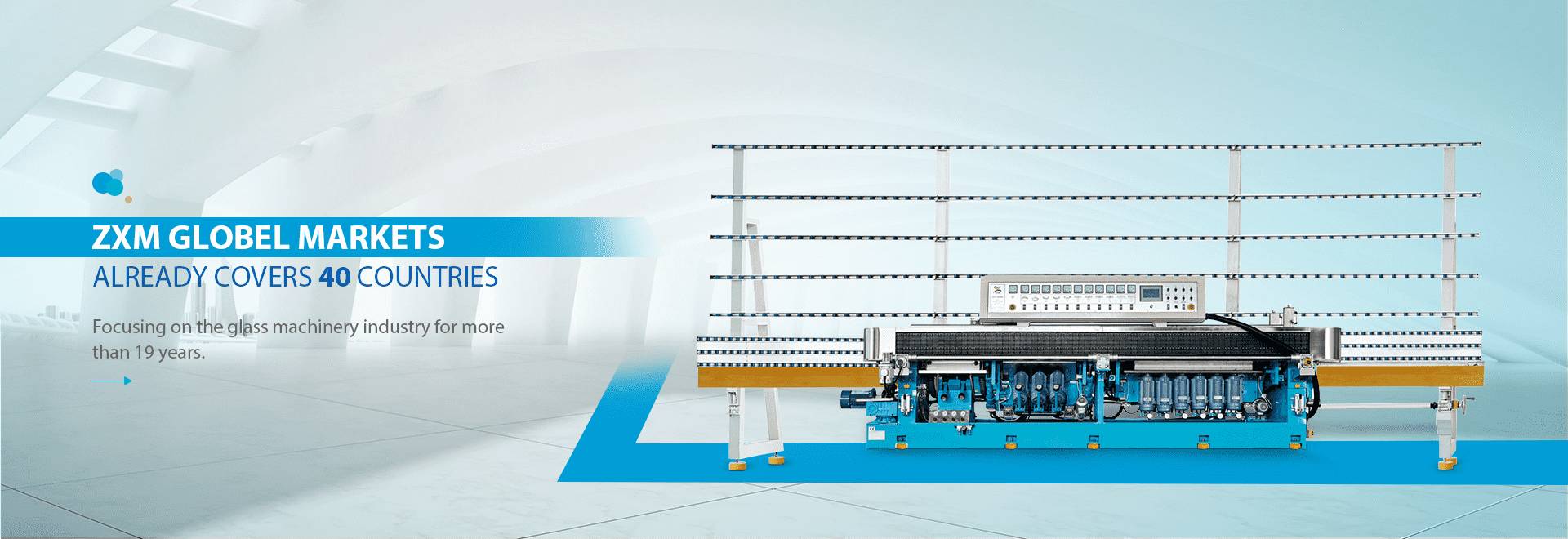

China Double Edger Machine - double edger flat edgers full automatic – Zhengxing

China Double Edger Machine - double edger flat edgers full automatic – Zhengxing Detail:

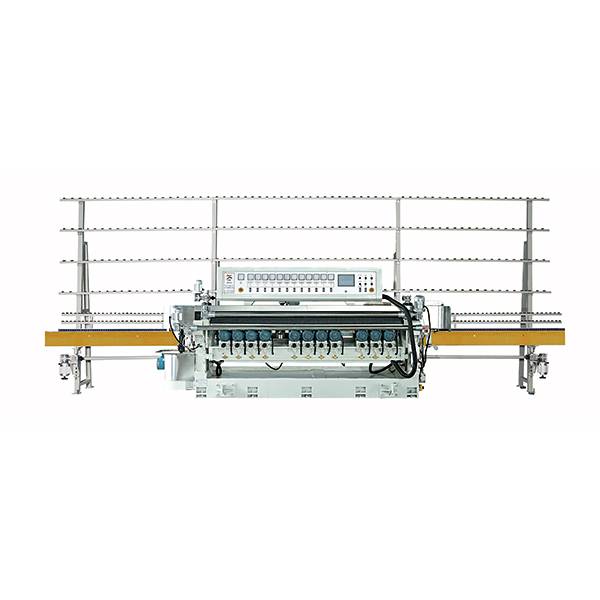

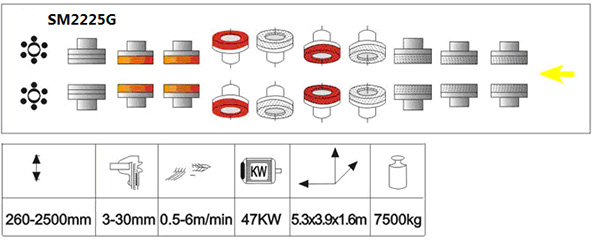

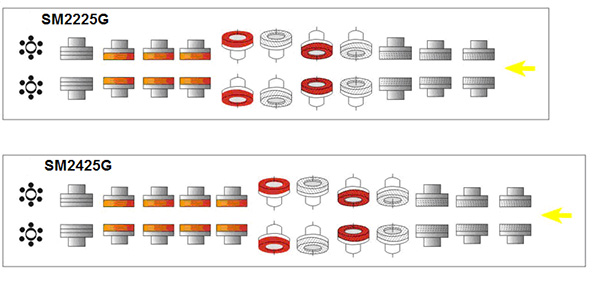

SM2025G

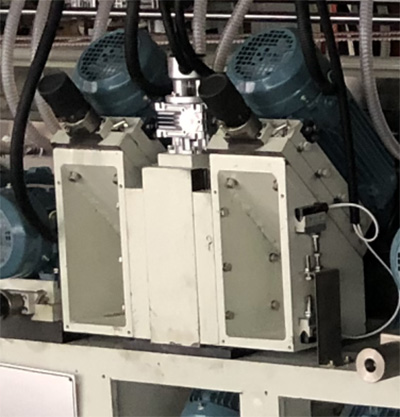

Ball screw and twin ball bearing guide system for width adjustment

Upper track system and upper arris motor

Driving system

Pneumatic polshing motors

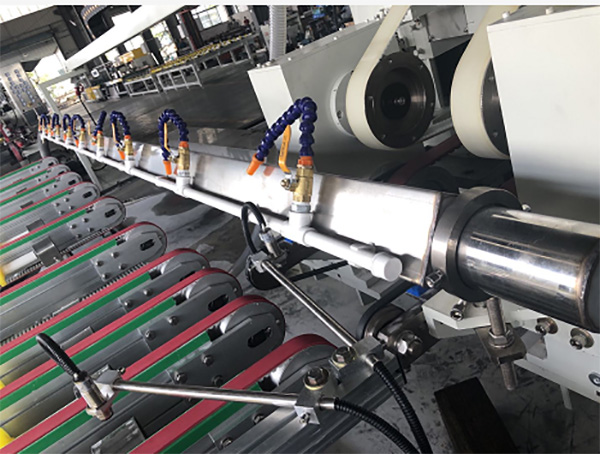

Dry air blade and water spraying nozzle

Machine Introduction

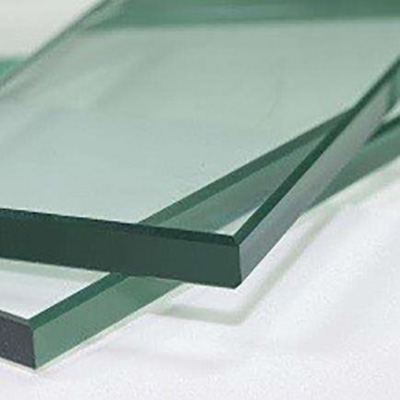

This machine is designed for polishing two opposite edges of glass at same time.

a) Control

This machine adopt Japanese Mitsubishi PLC control and 8” operator interface. The Screen shows every detailed parameters of glass. Each machine can be control by its own computer or controlled by main computer. The user’s right can be graded as operator/repair/administrator, preventing error happening, protect machine from misoperation.

b) High precision transmission.

The two conveyor timing belts are driven by variable Frequency motor, with feature of high precision, high speed, high synchronization.

c) Mobile grinding section movement.

The mobile grinding section moves along linear twin ball bearing guide. The transmission is implemented through ball screws, which is driven by motor with brake, the Max moving speed of grinding section can reach 8 meter per minute. This system also include a brake and gripping system, which can guarantee stable moving of the grinding section, low impact force. This structure can guarantee the stability of gripping force for big size glass, even after machine running a long period of time.

d) The edger has one movable support rail, which can be placed in middle of two conveyor to support glass from middle position to prevent glass from bending.

e) Upper track up&down system use sliding plate structure without stuck problem that traditional sliding sleeve system.

f) Positioning system.

Glass loading position system includes four parts: fixed rollers, moving air gripping system, aligning blocks(one left and one right), top air pressing rollers(one left and one right). Glass is precisely aligned and pressed tightly by the positioning system. This system guarantees the grinding precision and polishing effect.

g) Easy adjustment

The raise/drop of upper tracking system and upper arris motors are driven by motors. It can be set automatically according to different glass thickness.

h) Air Polishing system.

The polishing wheel is operated by air, which is controlled by PLC and electromagnetic valve, which can move forward/back according to glass position. This system can automatically compensate the wear of wheels, giving consistent pressure to glass and getting same polishing result.

The polishing motor moving system use High precision dural linear slide rail system.

i) Basement and frame: Are made of thick fabricated steel, which is treated by annealing furnace in our factory. With good stability and anti-torsional strength, anti-bending strength.

j) Motor

Use high precision, low vibration ABB motor.

The motor control system has protection function of overload/lack phase/short circuit, electronic parts use international brand, standard types, can be found easily in the market, which reduce customer’s maintenance cost, increase production efficiency.

k) Top/Bottom Transmitting conveyor adopt timing belts.

l) Lubrication: The twin ball bearing linear screw and guide rails are lubricated by automatic oil pump. The machine also equipped a manual lubrication pump, which lubricate the sliding surface..

m) Working speed adjustment: Through frequency inverter.

n) Water tank, water tray, top/bottom timing belt cover, linear guide rail/ball screw covers are made in stainless steel.

o) Amperometer meter: check the wheel pressure.

Technical parameters

|

Item |

Parameter | Range |

|

1 |

Spindles: |

20 heads. |

|

2 |

Min. glass width: |

260mm |

|

3 |

Max. glass width: |

2500mm |

|

4 |

Glass thickness: |

3mm-30mm |

|

5 |

Working Speed: |

0. 5m-7m/min |

|

6 |

Speed of width adjustment |

0-10000 mm/min |

|

7 |

Total power: |

50KW |

|

8 |

Working Air pressure |

0.15~0.8MPa |

|

9 |

Outer dimension |

5301×4421×1606 mm |

Product detail pictures:

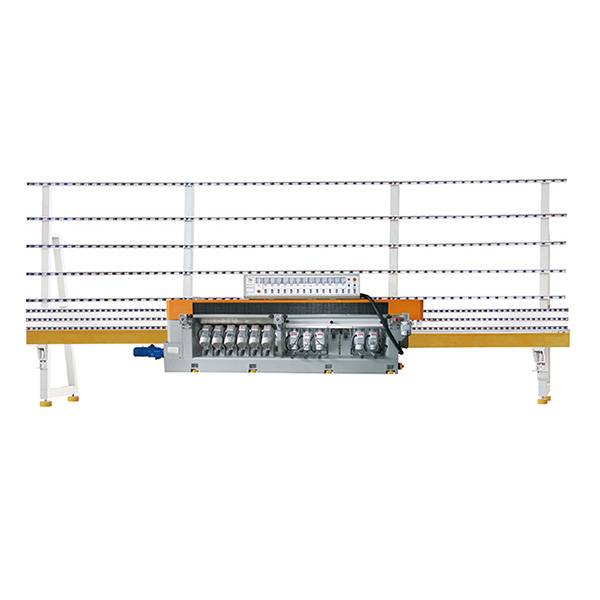

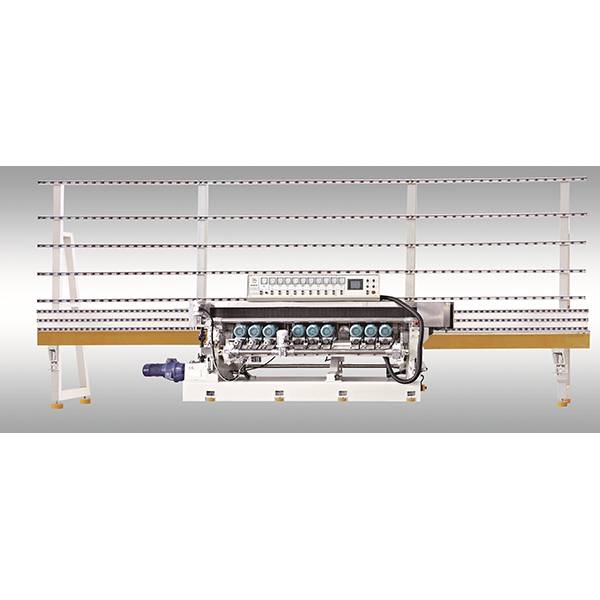

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for China Double Edger Machine - double edger flat edgers full automatic – Zhengxing , The product will supply to all over the world, such as: Guatemala, Czech, Madrid, We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.