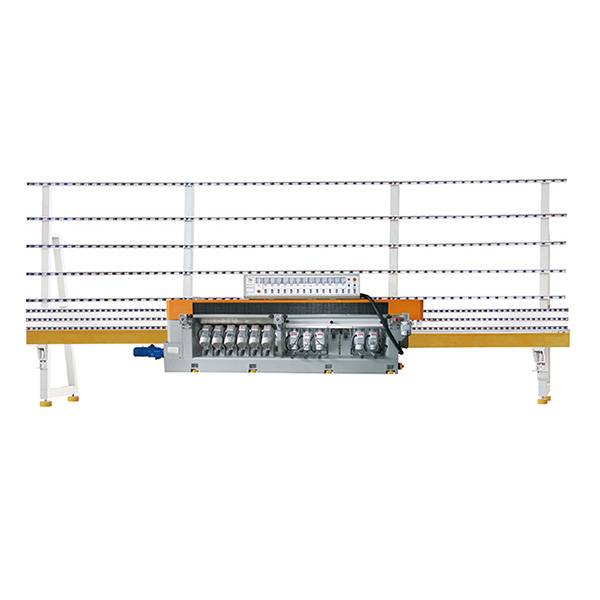

Best quality Glass Mitered Edge – 15 motors automatical ball bearing variable angle glass edging mitering machine – Zhengxing

Best quality Glass Mitered Edge – 15 motors automatical ball bearing variable angle glass edging mitering machine – Zhengxing Detail:

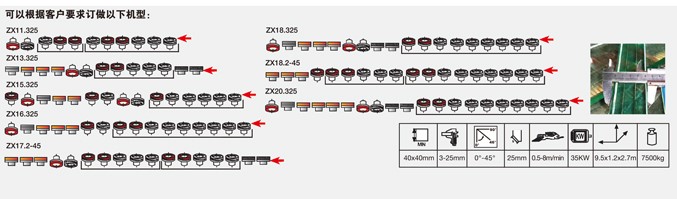

ZDM15.325

Lots of 20-30 motors edging/mitering machine made for glass and crystal processing

Machine Introduction

1. The first section 6 motors(No.1-No.6) process glass bottom edge and front miter edge (0-60 degree), 2 motors (No.7-No.8) for back arris seaming and 2 motors (No.9-No.10) for front arris seaming. No.11.No.12 and No.13 motors are for bottom edge grinding and final polishing when No.1-No.6 motors for front miter processing. The last two wheels are for front and back arris polishing. All process is finished at one travel.

2. This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx40mm) and heavy glass(4mx4m) processing. The top brackets structure can make conveyors running stably to work very small glass 40mm size.

3. The machine has a glass thickness protection mechanism. When wrong thickness glass is put in the machine. The machine will stop automatically. This protects the bearings from crushing.

4. The machine adopt PLC control and operator interface(Touch screen). The machine has 2 working modes, manual and fully automatic working mode. In automatic mode, the parameters of glas can be input through Touch screen. In manual mode, machine can be operated through the switch on the working panel.

5. Loading/off loading conveyor use timing belt. It can adjust height to set different glass removal..

6. Glass support frame use Aluminum extrusion bar, with plastic rollers.

7. The conveyor cover is made in stainless steel.

8. The conveyor bearings are lubricated by lubrication system, well designed oil route enable top and bottom bearings to get oil evenly.

9. The front conveyor movement is motorized. It can be adjusted through electrical button on working panel. The thickness is displayed on the screen. There is also a mechanical readout to show glass thickness.

10. The working speed can be adjusted via the frequency inverter.

11. The last 3 polishing wheel are felt polishing wheel, which give a very good finishing on glass. The water tank is separated.

12. The wheels tank for the variable angle 6 wheels use rotating system. The delicate water tank and water protection system under the conveyor between each water tank give a well protection for complete machine.

13. The angle can be show on screen.

14. The motor use high precision motor made by ABB, which is specially for beveling machine.

15. The processed glass surface is very bright and smooth, approaching to the original glass surface. This machine is also featured by wide processing range and easy operation.

Technical parameters

|

Angle change range |

0-45 degree. |

|

Wheel quantity for miter |

6 |

|

working Speed: |

0.4m-3.8m/min |

|

Grinding depth: |

3mm |

|

Max. miter width: |

30mm |

|

Glass thickness: |

3mm-25mm |

|

Min. glass Size: |

40mmX40mm |

|

Total Power: |

20kw |

|

Overall Dimension: |

8.6mx1.2mx3.5m |

|

Spindles: |

15 heads. |

Product detail pictures:

Related Product Guide:

With a sound business credit, excellent after-sales service and modern manufacturing facilities, we have earned an excellent reputation among our customers across the world for Best quality Glass Mitered Edge – 15 motors automatical ball bearing variable angle glass edging mitering machine – Zhengxing , The product will supply to all over the world, such as: Jeddah, Chicago, Macedonia, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.