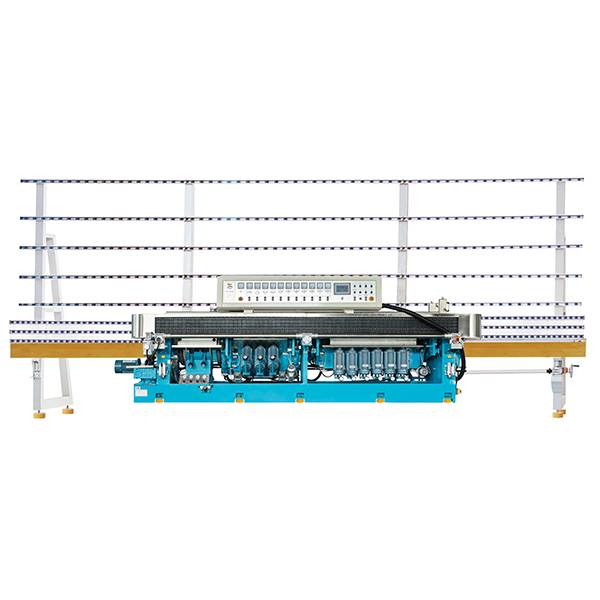

Best quality Glass Mitered Edge – 11 motors automatical ball bearing variable angle glass edging mitering machine – Zhengxing

Best quality Glass Mitered Edge – 11 motors automatical ball bearing variable angle glass edging mitering machine – Zhengxing Detail:

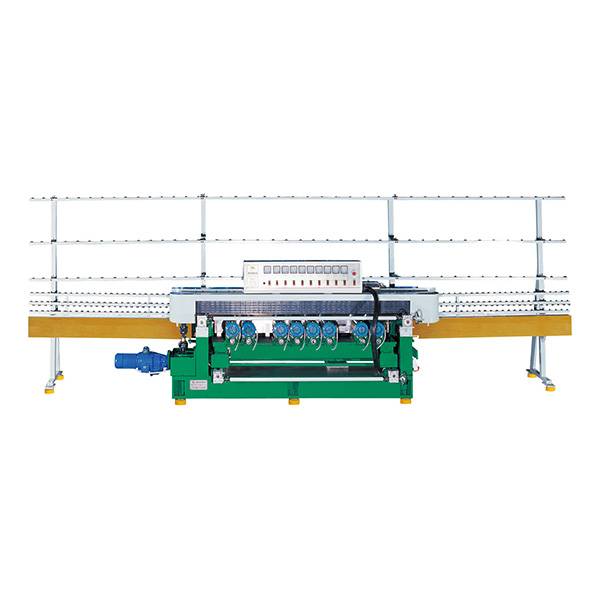

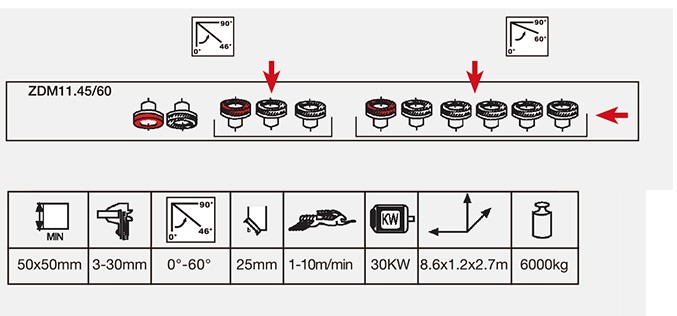

ZDM11.45/60

ball bearing conveyor

ball bearing conveyor

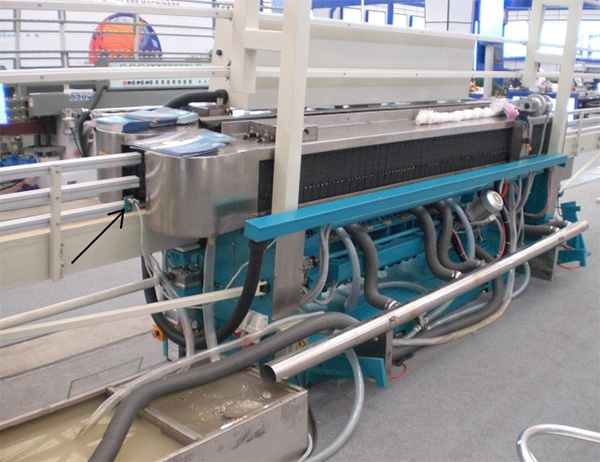

Stainless steel water circulating system

Very simple operation interface

Two Variable angle rotation system is the most prominent character

Machine Introduction

The Most important feature of this machine is that can make flat bottom edge and miter edge at one travel of glass.

Normal miter machine need two travels, first flat edge, then miter edge.

Description of the Equipment:

1. This machine has 6 motors(No.1-No.6) which can process glass bottom edge and front arris(0-60 degree), 3 motors (No.7-No.9) which can process glass miter edge and also bottom edge. with 2 motors for rear seaming. All process is finished at one travel.

To make flat edging/polishing, No.1-No.6 motors need to stay at ZERO degree and No.7-9 motor can be changed to 45 degree for front arris.

To make miter and bottom edge, No.1-No.6 motors can be adjused to the requested degree and turn No.7-No.9 motors to ZERO degree for bottom edge processing.

2. This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx40mm) and heavy glass(4mx4m) processing.

3. The machine has a glass thickness protection mechanism. When wrong thickness glass is put in the machine. The machine will stop automatically. This protects the bearings from crushing.

4. The machine adopt PLC control and operator interface(Touch screen). The machine has 2 working modes, manual and fully automatic working mode. In automatic mode, the parameters of glas can be input through Touch screen. In manual mode, machine can be operated through the switch on the working panel.

5. Loading/off loading conveyor use timing belt. It can adjust height to set different glass removal.

6. Glass support frame use Aluminum extrusion bar, with plastic rollers.

7. The conveyor cover is made in stainless steel.

8. Lubrication.

The machine equipped a automatic lubrication pump, which lubricate the front and back conveyor.

All the sliding surfaces (including front conveyor movement, grinding beam moving section, motor plates) are lubricated by oil system. The well designed oil lubrication system make sure machine’s life time and long-time smooth running.

9. The front conveyor movement is motorized. It can be adjusted through electrical button on working panel. The thickness is displayed on the screen. There is also a mechanical readout to show glass thickness.

10. The working speed can be adjusted via the frequency inverter.

11. The last polishing wheel is CE3 or X3000, not felt. The wheels tank is not separated.

12. The wheels tank for the variable angle 6 wheels and middle three wheel (Pos.7.8.9) use rotating system.

13. The angle can be show in screen.

14. The motor use high precision motor made by ABB, which is specially for beveling machine.

15. Water system

Water is circulated in the machine and stainless water tank. Wheel tank outlets connect with one stainless drain pipe which is very easy for installation. The square water tube for water inlet is connected with each wheel nozzle.

16. The processed glass surface is very bright and smooth, approaching to the original glass surface. This machine is also featured by wide processing range and easy operation.

Technical parameters

Technical Specification:

|

Spindles: |

11 heads. |

|

Angle change range |

0-60 degree. |

|

Angle change range |

0-45 degree |

|

Wheel quantity for miter |

6 |

|

working Speed: |

0.4m-12m/min |

|

Grinding depth: |

3mm |

|

Max. arris width: |

2.5mm |

|

Glass thickness: |

3mm-25mm |

|

Min. glass Size: |

40mmX40mm |

|

Total Power: |

20kw |

|

Overall Dimension: |

8.6mx1.2mx3.5m |

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Best quality Glass Mitered Edge – 11 motors automatical ball bearing variable angle glass edging mitering machine – Zhengxing , The product will supply to all over the world, such as: Provence, Nigeria, Philadelphia, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We've been looking forward to doing business with you!

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!